Frequently Asked

Questions

|

Question 1. Recently we celebrated 100 years of the

Otto Internal Combustion Engine Patent. Dozens of huge companies

have put enormous funds into what seems like all possible aspects of

engine theory, design and practice. What did they miss? What was so

hidden from them that made our engine so superior to today’s

conventional solutions?

Question 2.It looks like the AB Engine,

compared to a conventional engine with the same engine volume burns

less fuel for each working cycle. Does this make the AB Engine have

a smaller power output? (It was a question from a traditional engine

design specialist).

Question 3.What is the actual fuel efficiency of your

engine? How much are the fuel savings?

-

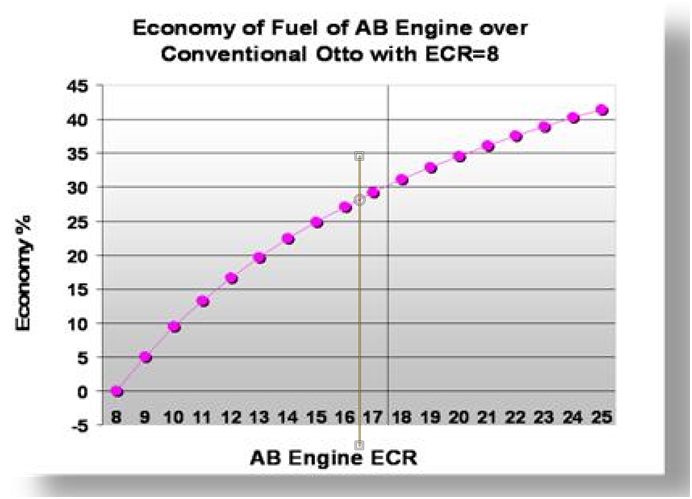

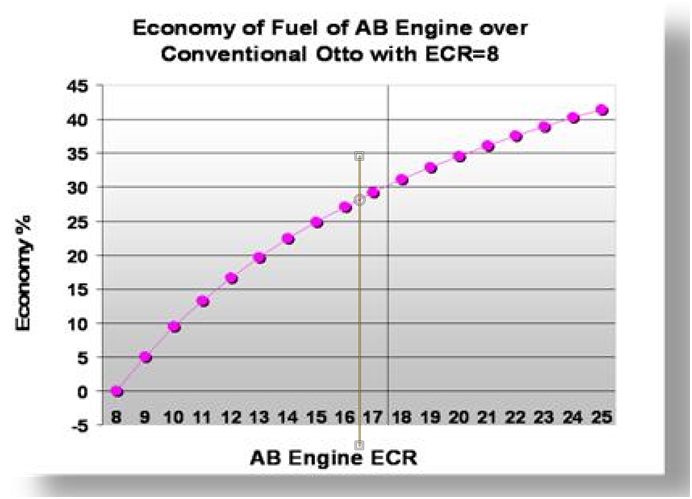

Answer. Independent

of the kind of vehicle that the AB Engine will be installed on,

including Hybrids, the engine itself will be more efficient with

converting burnt fuel to mechanical (or electrical) energy by

25-45%. See a detailed explanation on AB Engine efficiency in

comparison to conventional engines.. click here (PDF

document)

Question 4.Can your technology be applied for

Diesel engines and also benefit their fuel efficiency?

-

Answer. Yes

it will definitely benefit diesel engines. In case of using

diesel engines, they will be designed with increased

compression/expansion ratios, compared to traditional Diesel

engines, and also the AB Engine intake valve with the

controller. This will limit the amount of gas so the actual

compression of gas will be lowered enough to the point where

diesel fuel will be self ignited. For example: if a conventional

engine has compression ratio of 16-20 then the AB Engine for

diesel fuel with be designed with one of 25-30; this will give

increased expansion ratio though fuel efficiency while keeping the

diesel burning condition the same as in a conventional diesel engine. The benefits of using the AB Engine technology with

diesel fuel are beyond that of just of increased fuel efficiency.

Increased design compression ratio will allow (for both gasoline

and diesel fuel) simplified piston compression coils and allowed

and controlled leaks that will lead to less energy loss on coil

friction, this allows for Higher RPM engines with overall

increased power output.

Question 5.There are many alternative fuel

developments. How is your technology benefiting there? Is your

technology necessary in this case?

|

|

-

Question 6.Are there any advantages in your engine

design except fuel efficiency?

-

Question 7. Is

this a completely new engine design? Is it possible to modify an

existing conventional engine to meet your technology

requirements? What about all the engine inventions that are

related to improvement of conventional engines such as Fuel Port

e.t.? Are they still useful in design with your technology?

-

Answer. AB

Engine is based 100% on basic Otto gasoline and Diesel engine

designs. Because of this, the majority of modern improvements

can be used in an AB Engine design as well. It is not a rewired,

impractical and complicated engine design; it is just the next

level of significant improvements to gasoline and diesel

engines. Manufacturers and vehicles developers will have no

major problem in adapting AB Engine technology.

-

Question 8.Are there any disadvantages in using AB

Engine technology?

-

Answer. The

AB Engine team could not find any except that we are adding

additional engine elements such as the AB Engine Intake valve

with controller. Majority of modern vehicles already utilize

computers to control many engine aspects. We expect that AB

Engine technology will have impact on engine design and market

penetration similar to the invention of the Fuel Port, but with

lots more possible improving solutions as in engines as in

vehicles designs

-

Question 9.What are the practical applications to

the AB Engine? Is it applicable for Electric Generators?

-

Answer. Majority

of internal combustion engines customers will benefit from using

AB Engines such as Electro Generators, boats, cars, trucks,

ships and motorcycles and so on.

-

Question 10. How

does your engine contribute (or compare) to the most efficient

automobile design on today’s market – Hybrids?

-

Question 11. Sterling

engine developers and manufacturers claim that their engine

exclusively has the highest fuel efficiency theoretically possible. Since

AB Engine also makes this claim, can you explain this disagreement?

Can a Sterling

engine be competitive to an AB Engine.

-

Answer. Not

in practice. The Sterling

engine design is not pragmatic as a power source in cars, boats

or any other widely used vehicles. They are slow to start,

difficult to build with higher power output and expensive.

Sterling engine promoters tried to put this engine on the car

many times and unsuccessfully. Please read FAQs about all

aspects of Sterling

engine at --> Here

On the contrary, AB Engine can be

implemented immediately in almost all devices and equipment,

especially where the power of Otto or Diesel Internal combustion

engines is now in use. Even if an AB Engine is designed with a

compression/expansion ratio of 20, this will make it the same

efficiency as a Sterling

engine. See link --->Here

AB Engine can also be designed

with compression/expansion ratios even higher than 20 (30-35),

this will allow the use of high octane ratio gasoline fuels or

diesel fuels with a thermo-efficiency as high as 0.6-0.7, far

exceeding the 0.5 that the Sterling engine can achieve (as per

the Sterling engine FAQs).

Please note that

even engines with 0.5 thermo-efficiency are very good engines

that are not in any practical vehicles now.

December 27 2011 company was

granted by US. Patent

#8,086,386 Download PDF file of patent here.

|

.png)

.png)