AB Engine Technology and

Technology Applications

This section describes several

possible design realizations of the fuel efficient AB Engine depending

on the Internal

Combustion Engine (ICE) application. We would like to emphasize

that independent of which design solution is implemented, the AB

Engine Method will create the most fuel efficient ICE engine

theoretically possible! AB Engine is similar in fuel efficiency to

the Atkinson engine, but does not have the disadvantages of

implementing a complex mechanical solution. The AB Engine method

also delivers many “collateral” advantages beyond the

improvement in fuel efficiency such as low noise or silent

engines, low temperature and pressure exhaust gases (eco

friendly), linear power output with respect to RPM as well as

adaptable solutions to different fuel types and intake gas

conditions.

Watch it

on YouTube

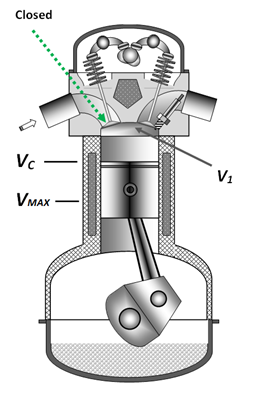

The main idea protected by patent consist of two parts.

-

Ratio

of maximum chamber volume to the minimum R=VMAX/VMIN is

higher than critical volume VC for

particular fuel type. Definition of critical Volume is given in US

patent first claims#8,086,386

It is important to understand that R is not

theoretically limited, it can be as high as desired from fuel

efficiency point of view for one cycle at maximum power output.

Practically, it is limited by the ratio at which the expanding

burnt gas-fuel mixture reaches the environmental exhaust

pressure PATM at

volume VE. and temperature TE The

ratio R can be even higher for engine designs that utilize

different kinds of fuel.

-

Engine designs

that utilize the second part of the method admit oxidizing gas to

the combustion chamber with a gas mass that is less than equivalent

to “Critical Volume - VC”

at initial gas temperatureT1 and

pressure PATM.

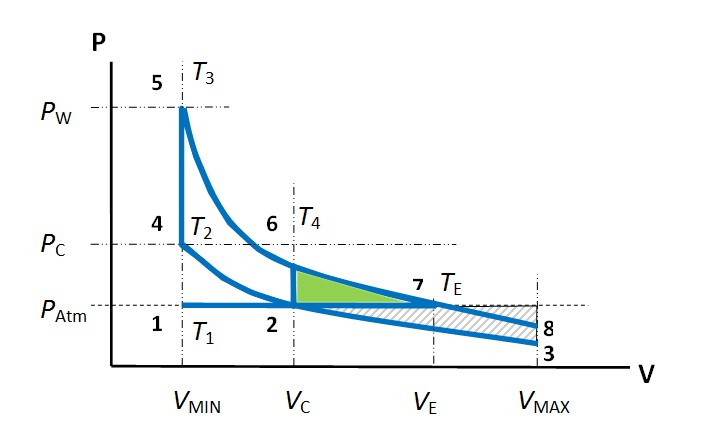

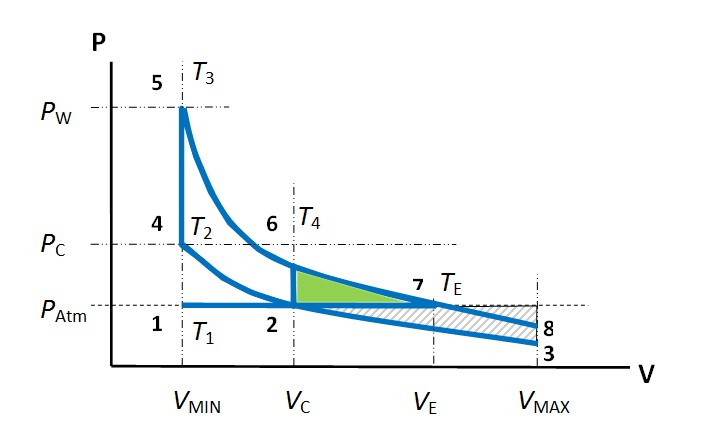

P-V Diagram

(on the right) shows The "Alexander Bakharev (AB) engine P-V Cycle" of

ICE at maximum power output. Diagram is outlining conventional engines

(Otto, Diesel) cycles 1-2-4-5-6-2 and

AB Engine Cycle 1-2-3-2-4-5-6-7-8-7

Green area 2-6-7 represent

additional power generated by AB Cycle compare to conventional engine

defining higher AB engine fuel efficiency

Some possible design

solutions:

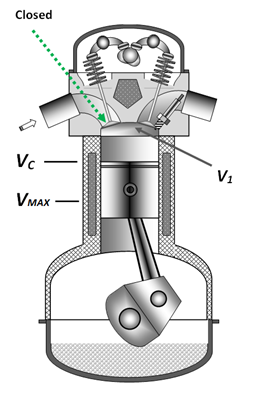

Solution 1.

Engine design with fixed high pressure

Intake valve closing at a fixed level allowing gas intake below Critical

volume. This solution is well described in the patent with step by step

analysis of the Thermodynamics behind the method. (Picture bellow)

Applications: Excellent

solution for stationary or mobile power generators such as:

- Houses or offices

- Boats, yachts and large

ships (marine applications)

- Hybrid solutions for cars and

trucks

Advantages:

- The most inexpensive

implementation of the AB Engine Method and does not require the

design of unique engine parts.

- Excellent Design for an ICE

in Power generators with fixed

RPM and

particular fuel type.

Disadvantages:

All the disadvantages of ICEs with

fixed intake valves such as:

- Declining power output with

increase in RPM; this is not a disadvantage for Power Generators

since they can be designed and optimized for a particular engine

RPM.

- Inability to adjust actual

compression ratio to particular type of fuel or intake gas

temperature and pressure.

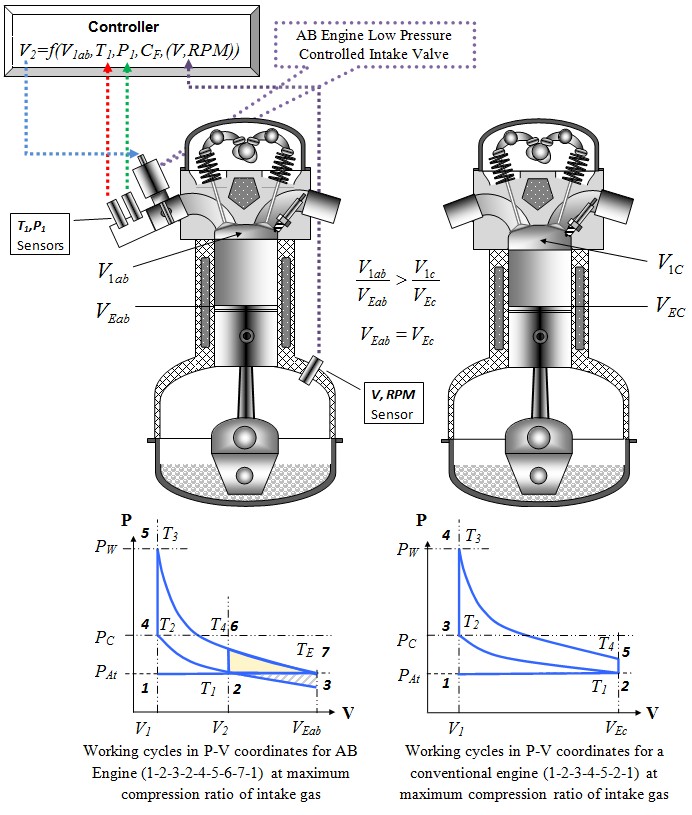

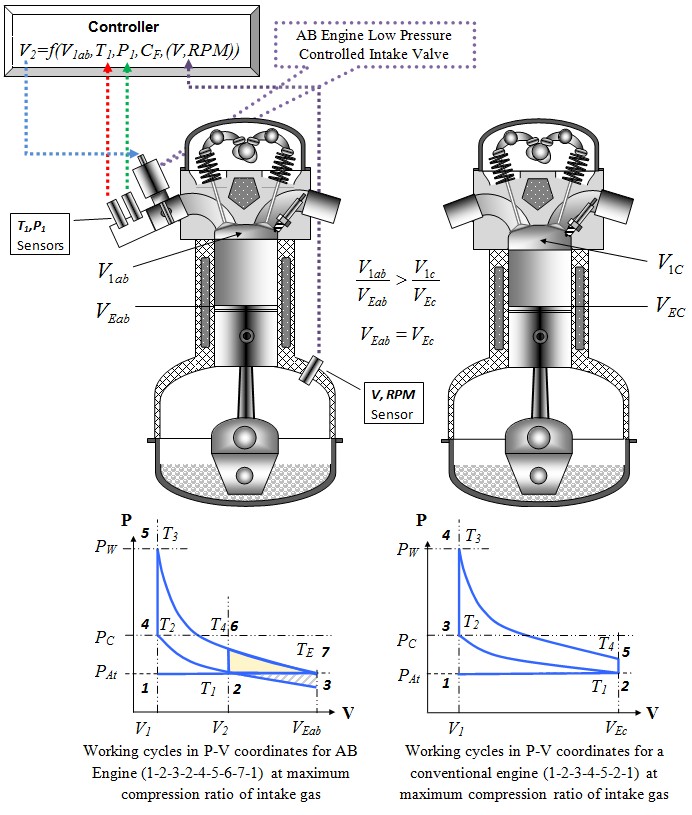

Solution 2.

Engine design with Time Variable

Valve (TVV)

This is a solution that requires

almost no changes to an existing engine that is already equipped

with TVVs and PC controllers. There is a need however to reprogram

the controller for specific parameters (variables) that are

essential for executing the AB Engine Method. It is also necessary

to implement sensors such that measure: temperature, pressure, RPM,

fuel type, combustion chamber and piston positions. Many sensor

solutions are already used in modern day technologies and they can

be adapted to the AB Engine Method.

Applications:

This is an excellent solution for

cars, motorcycles, trucks, airplanes and mobile Power generators

ICEs. This variant is suited for extreme weather conditions and

large altitude and atmospheric temperature/pressure changes.

Advantages:

-

Excellent for extreme weather

conditions and large altitude and atmospheric

temperature/pressure changes.

-

The TVV and PC controller

make this solution adaptable to almost any type of application.

-

Great engine dynamics

-

Easy to adapt to any fuel

type

-

Engine can start up with

gasoline and continue with Diesel

-

Easy to adapt to an existing

TVV technology

Disadvantages:

|

|

Solution

3.

Engine design with an AB Engine

Controlled Valve or Damper. This

solution is well described in the section of "Technology

Presentation" with

step by step analysis of the P-V diagram behind the method.

This is one of the AB Engine team's

favorite solutions. This technology is similar to TVVs, but has a

different and unique implementation. This technology is described in

detail in our ‘Technology Presentation” section, but there we did

not disclose all the advantages of this variation.

Applications:

This is an excellent solution for

cars, motorcycles, trucks, airplanes and mobile Power generator ICEs.

This variant is also suited for extreme weather conditions and large

altitude and atmospheric temperature/pressure changes. THe solution

is also adaptable to almost any type of application.

Advantages:

- This solution will provide the highest fuel efficiency

theoretical possible for internal combustion engine

- AB Engine Valve-Damper is applicable to single piston or

multiple piston engines. One of the great advantages of this

implementation is works with “normal” pressures and temperatures

of intake gas which simplifies the valve control and allows for

inexpensive solutions such as electromagnets for example.

- It simplifies the

valve-damper design because it combines two functions, it can be

used as a valve that opens and closed at specific times and

piston locations or

work as a damper creating gas flow resistance at higher engine

RPM.

- Excellent for extreme weather

conditions and large altitude and atmospheric

temperature/pressure changes. The solution is also adaptable to

almost any type of application.

- Great engine dynamics

- Easy to adapt to any fuel

type

- Engine can start up with

gasoline and continue with Diesel

- The best feature of the AB

Engine Valve-Damper is that multi-piston engines would only need

one valve at the manifold entrance. When acting as a damper it

creates gas flow resistance and ensures optimal actual

compression for any kind of fuel or intake gas condition. For

many ICE applications it is possible to use Valve-Damper without

PC controller adjusting fixed Damper position manually for

particular fuel type or "summer-winter" intake gas conditions. I

would separate it as a Solution

4. This

solution is excellent, but

not limited, for

engines working with constant RPM.

Disadvantages:

The AB Engine team does not

see any significant disadvantages in using an AB Engine

Valve-Damper. As this is a highly flexible solution, there is no

need to implement it in more rigid ICE applications such as

those described in solution one, that is, low power house

generators etc...

|