|

Technology Presentation |

|||||

|

|

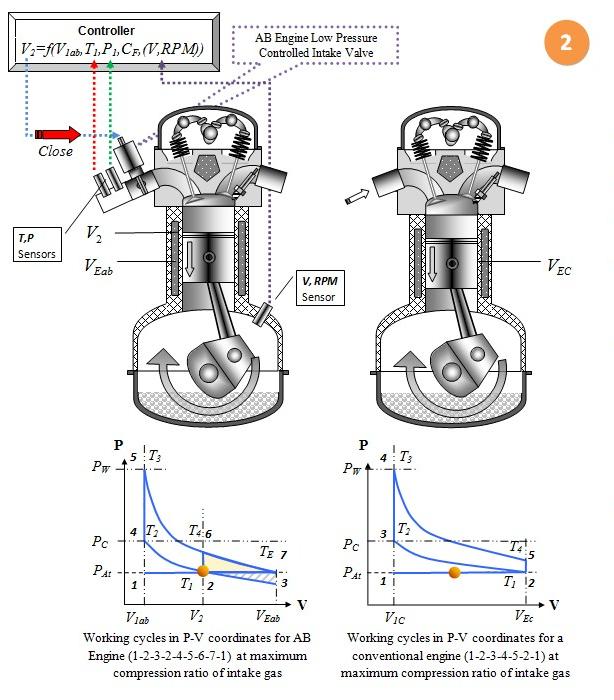

Intake Stroke Stage - 2

This Intake Stroke is very important for the AB Engine: · AB Engine Piston has reached V2, the position calculated by the AB Engine controller at the beginning of the intake Stroke. · Controller sent the closing signal to the AB Engine Low Pressure Intake Valve upon reaching V2 and is now in a closed position. · High pressure Intake Valve is still in the Open position in both engines · Gas flow is stopped in the AB Engine but continues in the conventional one · This step is the essence of AB Engine technology, when the AB Engine controller provides an optimum amount of gas, taking into account all design, experimental and thermodynamic variables for the fuel-gas mixture ignition whether diesel or gasoline. · At this stage, the AB Engine Low Pressure Controlled intake Valve is ideal for gas intake manipulation at the relatively “soft” environmental conditions. Here, the pressure and temperature variables do not require any “super” temperature and pressure resistant materials, resulting in simplified mechanics for opening and closing the intake valve. The Low Pressure Controlled Intake Valve can be powered by any kind of input such as inexpensive electric, hydraulic or pneumatic mechanical designs. · An additional benefit to using the Low Pressure Controlled Intake Valve is that it can provide minimum power for the engine in case of valve opening malfunction. It can be design with controlled gas leak that provides necessary minimum amount of gas for minimum engine power output.

|

||||

|

|

|||||

|

|

|||||