|

Technology Presentation |

|||||

|

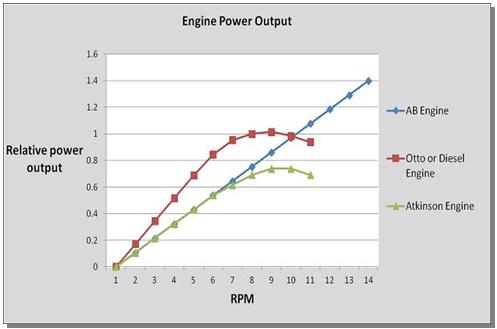

AB Engine power output Someone can say that if AB Engine is actually simulating Atkinson engine with similar fuel efficiency then it will have the same problem with Power Output compare to conventional Otto or Diesel designs. Because AB Engine has a significant difference with Atkinson engine as from thermodynamics as from design point of views it is an incorrect assumption. Otto, Diesel and Atkinson engines have fixed volume to fill by fuel-gas mixture during intake cycle. A well known problem for this design is inability to keep cycle power output constant as higher engine RPM because of increasing resistance to gas flow and as a result incomplete filling of intake volume by fuel-gas mixture. Picture below shows the typical charts of dependency of Power Output from RPM for Otto or Diesel and Atkinson engines.

Comparison of AB Engine Power output to Otto, Diesel and Atkinson engines from RPM |

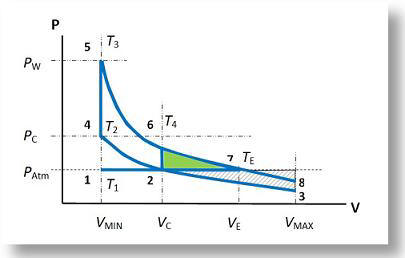

AB Engine does not have this problem. The main principle of AB Engine method is filling the intake the volume that is the same as engine volume but with limiting amount of fuel-gas mass that makes optimal actual compression for particulate fuel. P-V diagram of AB Engine working cycle below shows that is order to fill AB Engine with maximum amount of gas its flow is interrupted on point 2 during intake cycle. As higher RPM and higher gas flow resistance point 2 can be adjusted automatically closer to point 3 up to the maximum RPM when point 2 and 3 are the same. A simple estimation shows that in order to reach it RPM has to be in several times higher than in conventional engines having gas flow mass higher than in conventional engines. That means that even with the same gas mass flow through the same manifold but better fuel efficiency power output of AB Engine will be higher on the same percentage as higher engine fuel efficiency.

AB Engine thermodynamic cycle with maximum cycle power output. |

||||

|

|||||

|

|

|||||