|

Technology Presentation |

|||||

|

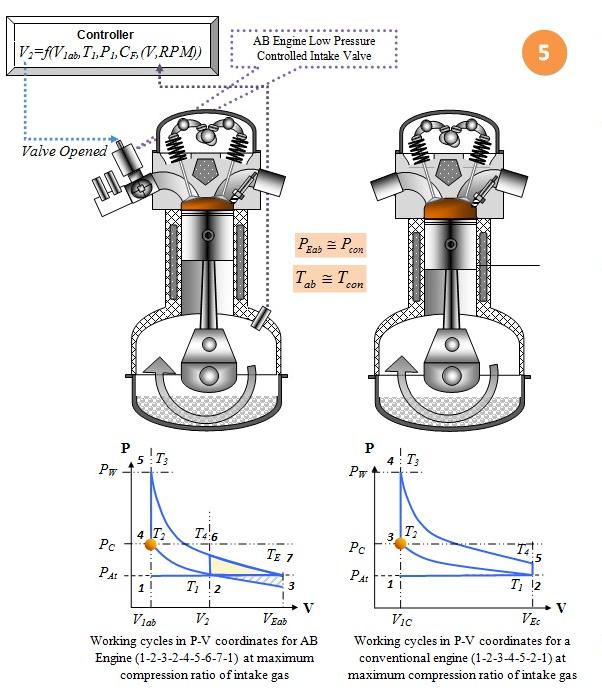

Compression Stroke Stage - 2

· AB Engine and conventional engine pistons reach the V2 position · Temperature and Pressure in the AB Engine Combustion chamber are the same as in a conventional Engine. This is what the AB Engine Controller and AB Engine Low pressure Intake valve were invented for. With engine designs of maximum volume VE, the AB Engine needs to limit the amount of intake gas in order to reach the same gas compression conditions as in a conventional one when using equivalent fuels · This point is very important for engine optimization. Even though the task of the AB Engine controller and Low pressure Intake valve is to provide the same conditions of compressed gas/fuel mixture, AB Engine is always superior at this task. The same AB Engine can use different kinds of fuel, those of different Octane rating and Diesel/Gasoline. In order to derive the most benefit from different fuels, AB engine creates the most optimum compression conditions taking into account outside atmospheric conditions and adjusting V2 as well. Adjustable V2 is highly beneficial in compensating for gas flow resistance through the manifold track as the engine RPM increase. Contrary to a conventional engine, adjustable V2 allows for linear increase in power output with increasing RPM. Pressure conditions of gas during intake stroke in the AB Engine combustion chamber are always lower than in a conventional engine that provides relatively more gas flow with the same manifold design. This means that despite lower amounts of gas in one cycle of the AB Engine, the maximum power output will be higher than in a conventional one. This is one of AB Engine’s major advantages

·

At this stage,

the engines are ready for fuel ignition in the case of gasoline fuel or

are igniting in the case of Diesel fuel

|

||||

|

|

|||||